Looking for the Best GFRP Rebar Manufacturer in india

We manufacture and supply premiun quality Glass Fiber Reinforced Polymer Rebar in india

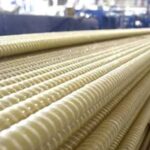

Dura Composites was established with a vision to bring technological and material-tech innovation to the building & construction material space. To align with our strong & long-term vision, we introduced Glass Fiber Reinforced Polymer (GFRP) Rebars, a corrosion-resistant advanced composite material that reinforces structures with superior durability.

As a trusted GFRP rebar manufacturer in India, we ensure that our GFRP bars outperform traditional steel with twice (2X) the strength, three times the lifespan, and nine times the lighter weight. With GFRP rebars, our focus is strongly bonded to greener and sustainable construction.

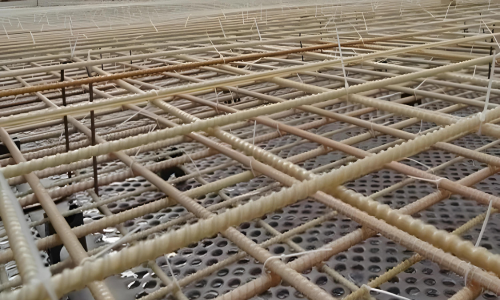

GFRP bars are used as an alternative to traditional steel reinforcement bars (rebar) in concrete structures. They offer excellent corrosion resistance, as they are not susceptible to rust or chemical degradation. GFRP bars are lightweight approximately 75% lighter than TMT bars, making them easier to handle and transport, and they have a high strength-to-weight ratio, providing comparable or even superior structural performance to steel.

Dura Composite’s Glass Fiber Reinforced Polymer (GFRP) bent rebar is specifically engineered to provide high strength and durability while maintaining its designed shape. Unlike traditional steel reinforcement, which requires on-site bending, GFRP bent rebar is pre-formed to the required angles, ensuring precision and ease of installation. Its composite structure, consisting of glass fibers embedded in a polymer matrix, offers superior corrosion resistance and longevity compared to steel rebar.

Dura Composite GFRP Dowel Bars serve as load transfer mechanisms between joints within concrete slabs. They establish a mechanical linkage between slabs while accommodating horizontal expansion and contraction of the concrete itself. This feature reduces deflection at joints and minimizes stress on the slabs. Unlike steel dowel bars prone to corrosion, Dura Composite Glass Fibre Dowel Bars are corrosion-resistant, ensuring longevity and meeting shear capacity needs.

We manufacture and supply premiun quality Glass Fiber Reinforced Polymer Rebar in india

GFRP is a cost-efficient product that reduces the overall cost of the project

GFRP, unlike Steel, does not oxidise on exposure to water and air. It is a non- corrosive product.

GFRP rebars do not conduct Electricity nor Heat. This leads to higher safety of the project and the people around it.

GFRP rebars are 1/4th the weight of similar dia steel rebars. Lowering costs of transportation and labour handling.

GFRP rebars have tensile strengths above 1000 MPa. In comparison, Steel rebars usually have it around 550 Mpa.

Production and usage of GFRP help reduce CO2 emissions by at least 43% over Steel rebars

We manufacture and supply premiun quality Glass Fiber Reinforced Polymer Rebar in india

Dura Composites has been a game-changer for us. The cost savings and ease of use have made our residential construction more efficient, without compromising on quality. The lightweight yet robust materials have simplified our installation process while enhancing the structural integrity of our homes, making them a smart investment for long-term sustainability.

We used Dura Composites’s NEO-BENDS for NHAI drainage structures, and the design accuracy, fast installation, and major cost savings made a significant impact on our project! The durability of their products ensures long-term performance, reducing the need for frequent maintenance. We are confident that their innovative solutions will continue to add value to large-scale infrastructure projects.

Dura Composites’s commitment to quality and prompt service has ensured seamless execution, making them our go-to choice for reliable solutions. Their ability to customize products to meet our project needs has contributed to our overall efficiency. We highly recommend their solutions for infrastructure projects requiring durability and precision.

Dura Composites’s products are incredibly easy to use and install. The fast installation process has helped us meet project deadlines efficiently, reducing both time and labour costs significantly. The durability and long-term performance of their products have also minimized maintenance efforts, ensuring hassle-free operations for our projects.

Dura Composites has been a game-changer for us. The cost savings and ease of use have made our residential construction more efficient, without compromising on quality. The lightweight yet robust materials have simplified our installation process while enhancing the structural integrity of our homes, making them a smart investment for long-term sustainability.

We used Dura Composites’s NEO-BENDS for NHAI drainage structures, and the design accuracy, fast installation, and major cost savings made a significant impact on our project! The durability of their products ensures long-term performance, reducing the need for frequent maintenance. We are confident that their innovative solutions will continue to add value to large-scale infrastructure projects.

Dura Composites’s commitment to quality and prompt service has ensured seamless execution, making them our go-to choice for reliable solutions. Their ability to customize products to meet our project needs has contributed to our overall efficiency. We highly recommend their solutions for infrastructure projects requiring durability and precision.

Dura Composites’s products are incredibly easy to use and install. The fast installation process has helped us meet project deadlines efficiently, reducing both time and labour costs significantly. The durability and long-term performance of their products have also minimized maintenance efforts, ensuring hassle-free operations for our projects.

Dura Composites has been a game-changer for us. The cost savings and ease of use have made our residential construction more efficient, without compromising on quality. The lightweight yet robust materials have simplified our installation process while enhancing the structural integrity of our homes, making them a smart investment for long-term sustainability.

We used Dura Composites’s NEO-BENDS for NHAI drainage structures, and the design accuracy, fast installation, and major cost savings made a significant impact on our project! The durability of their products ensures long-term performance, reducing the need for frequent maintenance. We are confident that their innovative solutions will continue to add value to large-scale infrastructure projects.

Learn how glass fiber rebar outperforms steel with superior corrosion resistance, lightweight strength, non-conductivity, and a longer lifespan.

Learn why GFRP rebar is replacing steel rebar in concrete structures with superior strength, corrosion resistance, and sustainability benefits.

Choosing the right GFRP rebar manufacturer plays an essential role in the success of your construction project. By evaluating the…

GFRP (Glass Fiber Reinforced Polymer) rebar is a high-strength, corrosion-resistant alternative to traditional steel reinforcement. It is made from fiberglass and a polymer resin, making it durable and long-lasting, especially in harsh environments.

GFRP rebar offers some game-changing advantages, including:

Our GFRP rebars adhere to international quality standards, ensuring high performance and durability. We are committed to providing products that meet or exceed industry benchmarks for higher levels of safety and reliability. Additionally, we are ISO 9001:2015 certified and our products are made in adherence to the product specifications mentioned in GFRP BIS Code – IS 18256: 2023. This guarantees that our manufacturing processes follow strict quality management standards to deliver consistent and reliable products.

GFRP rebars are made to outperform traditional steel rebars, offering three times the lifespan due to their corrosion-resistant properties. Unlike steel, which deteriorates over time, especially in harsh environments, GFRP rebars remain unaffected, ensuring enhanced durability and zero maintenance needs throughout its life span.

Installing GFRP rebar is similar to traditional steel rebar. However, there are certain important considerations like:

GFRO rebars are 25-30% cheaper in comparison to steel rebars in cost. Moreover, the indirect cost savings due to lower logistical needs, lower labour costs, reduced wastage, and negligible lapping costs contribute to their overall efficiency.

Yes, we provide competitive pricing and bulk discounts for large-scale construction projects. Please fill out the inquiry form on our website, and our sales team will connect with you to discuss your project details and provide the best quote price.

o place an order, fill out the inquiry form on our website or contact our sales department directly via email or phone. Our team will assist you with product selection, pricing, and order placement.

The minimum order quantity varies depending on the product specifications, and our sales team will provide detailed information based on your requirements.

Yes, we offer nationwide delivery across India. Our logistics network ensures timely and safe delivery of our products to your project site, regardless of location.

The lead time for manufacturing and shipping depends on the order size and product specifications. Typically, standard orders are processed and shipped within 1-2 weeks. For customized or large orders, the lead time may be different. Our team will provide an estimated delivery schedule upon order confirmation.

Yes, at Duraneo, we offer customized FRP/GFRP rebars to meet specific project requirements. Our advanced manufacturing processes allow us to produce rebars in various sizes and shapes, including bent forms, to suit your construction needs.

Get in touch with us – we’re here to help and eager to hear from you!

Address

Plot no. D-2, MIDC Umred Nagpur MH 441203 IN.

+91 7038850006, +91 8669995445